EQUIPMENT

NW-103

NW-103

Nonwovens Electrospinning System for Pilot Production

Adoption of PLC Control.

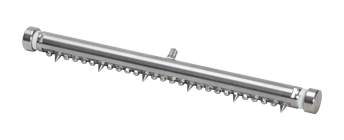

High speed and uniform spinning of nanofibers with pipe/multijet spinnerets.

The model NW-103 is an electrospinning system to spin nonwovens sheets. With solutions suh as PVDF, PAN and PVA, nanofibes of which diameters are from several tens of nanometers to several micrometers can be spun using electrospinning method.

Spinning nonwovens of 100um thickess

-

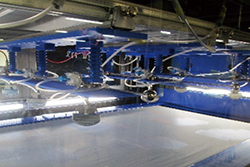

- High speed spinning of nanofibers on the 850mm-wide belt

- The NW-103 integrates spinnerets on 4 rows of rails and can spin 850mm-wide nanofiber sheets (effective width at 680mm).

- PLC control enabling easy connection of Roll-to-Roll unit

- With PLC (Programmable Logic Controller) control the interface with a user’s equipment such as Roll-to-roll unir was made easier.

Selection of pipe or multijet spinnerets for solutions to spin. A variety of solutions can be spun into nanofibers by selecting pipe spinnerets or multijet spinnerets (MJS). - Programmable left/right traversing and spinning distance

- Left/right traversing distance and speed and spinning distance can be easily programmed.

- 100um or thicker membranes

- Connection of a negative 10kV high voltage supply to the collector (conveyor belt) creates membranes of 100um or thicker.

(Patented) - Use as a pilot production machine

- By the combination of Roll-to-roll unit and/or an environmental controller the NW-103 can be used as a stand-alone system or a pilot production system.

- Safety features and easy operation

- Considering operators’ safety , safety features such as a high voltage interlock, a door lock, strengthened glassglass, instant high voltage discharge, a prefilter and emergency switches are equipped. Parameters to spin nanofiber sheets can be easily programmed with a 10-key controller.

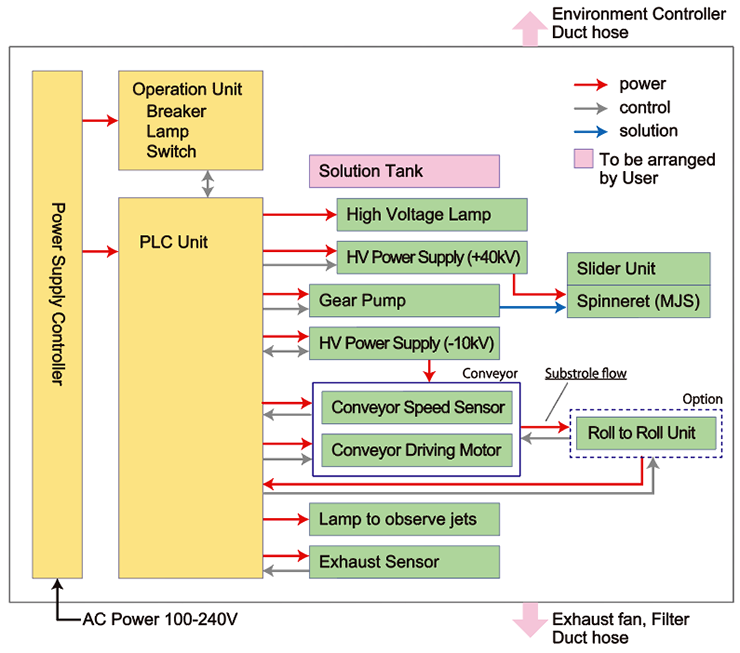

NW-103 system diagram

Performance

| Model name | NW-103 |

|---|---|

| Purpose of use | Research and development of nanofibers |

| Typical nanofibers to spin | Nonwovens 850mm-side steel belt / Effective width: 680mm |

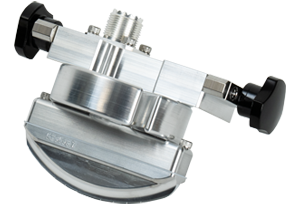

| Spinneret | Pipe Spinneret, Multi-jet spinneret (MJS), BNP (Bit Nozzle Pipe) spinneret (Quantities, number of holes and arrangement will be changed in accordance with solutions and conditions.) |

| Standard collector(Steel belt) | Steel belt |

| Control | PLC / Touch panel |

| Spinning distance | 100 to 300mm |

| High voltage power supply (Positive polarity) | 0.5 to 40.0kV |

| High voltage power supply (Negative polarity) | 0.0 to -10.0kV |

| Traverse speed | Traversing range: 100mm (+/- 50mm) Traversing speed: 0 to 100mm/sec |

| Conveyor speed | 10,000mm/min (max.) |

| Dimensions (except protrusions) | 2530W x 1720D x 2000H (mm) |

| Weight | 1300kg or less |

| Gear pump | 3 units can be installed |

| Feed rate of solution pump 1, 2, 3 |

50 to 500ml/hour |

| Solution viscosity | 100~5000mPa・S |

| Capacity of solutions tank | 430W x 230D x 280H (mm) |

| Lamp | For chamber and spinnerets |

| Safety devices | ・Safety interlock ・Door lock ・Emergency switch ・Signal tower ・Exhaust sensor ・Immediate shutoff of high voltage output after POWER OFF ・Immediate shutoff of high voltage output when overcurrent flows. |